Key Equipment

Our continual investment in cutting-edge equipment reflects our commitment and unwavering focus on delivering products that meet the highest industry standards.

Prototyping

Europlacer iineo ii-N1

Best in class prototyping: Top-of-the-line pick and place machine, supporting large format boards up to 1610x600mm. More assemblies with faster turnaround times.

Fast setup and changeover: Handle 264 unique components on a single machine, including placement of loose components and solder balls. Tenfold reduction in SMT setup and changeover times.

Soldering

Asscon VP7000 Vacuum

Vapour Phase Oven

Unmatched soldering quality: Delivers void rates below 1% by utilising vacuum vapour phase technology, ensuring reliable solder joints even in high-complexity assemblies.

Controlled atmosphere: Prevents oxidation during reflow, enhancing the longevity and durability of the finished product.

Inspection and Testing

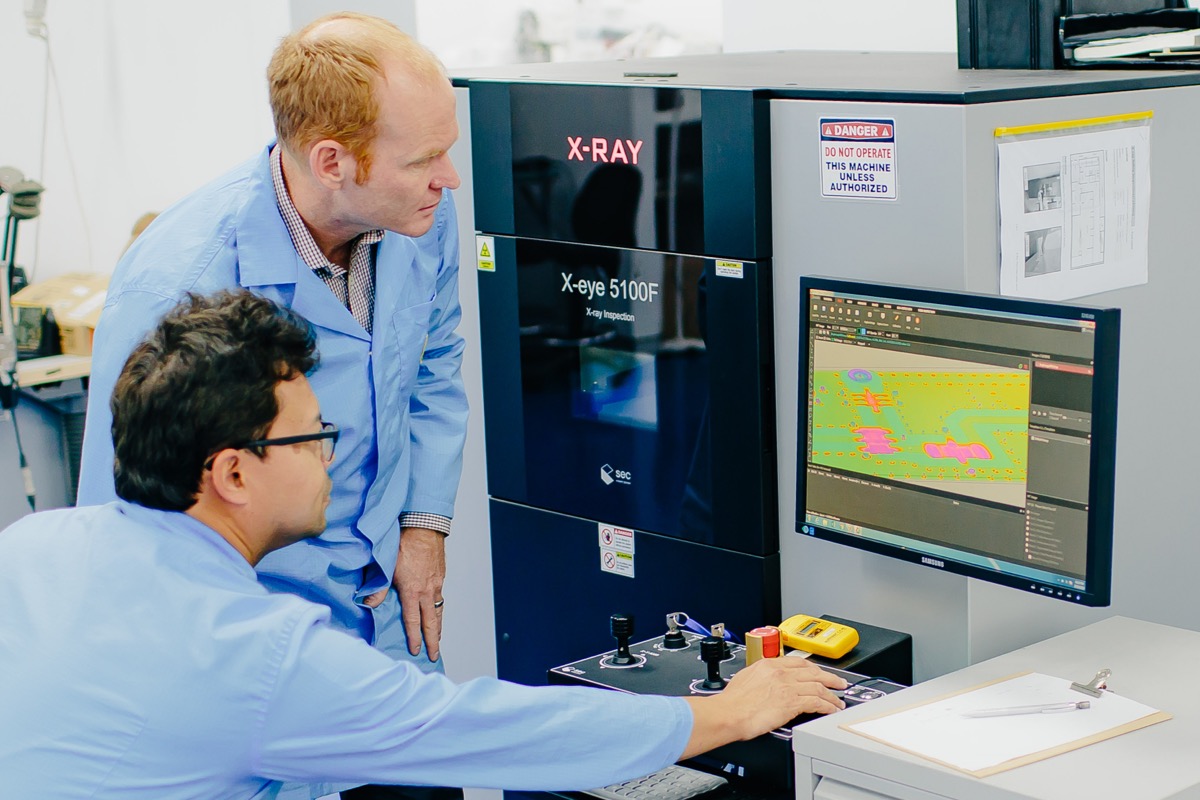

X-eye 5100F X-Ray Inspection

Non-destructive testing: A 100kV micro-focus X-ray and high-resolution detector allows detailed inspection of components, semiconductors, and hidden solder joints like Ball Grid Arrays (BGA).

Pinpoint accuracy: Detects voids, solder fractures, and misalignments, ensuring the reliability of complex assemblies.

Inspection and Testing

Zenith Alpha HS+ 3D AOI (Automated Optical Inspection)

AI-powered accuracy: Uses advanced algorithms to detect defects, misalignments, and inconsistencies with exceptional precision.

3D imaging: Provides comprehensive analysis by inspecting solder joints and component height for thorough quality assurance.

Inspection and Testing

SPEA 4060 Flying Probe Tester

Unmatched coverage and accessibility: Dual-side probing and multi-mode operation allow full access to large, complex boards (up to 20kg), ensuring comprehensive fault detection and high accuracy across all components.

High-speed, scalable performance: Delivers industry-leading throughput with 180 touches per second, handling diverse PCB configurations and sizes for fast, efficient, and scalable testing.

Rework and Repair

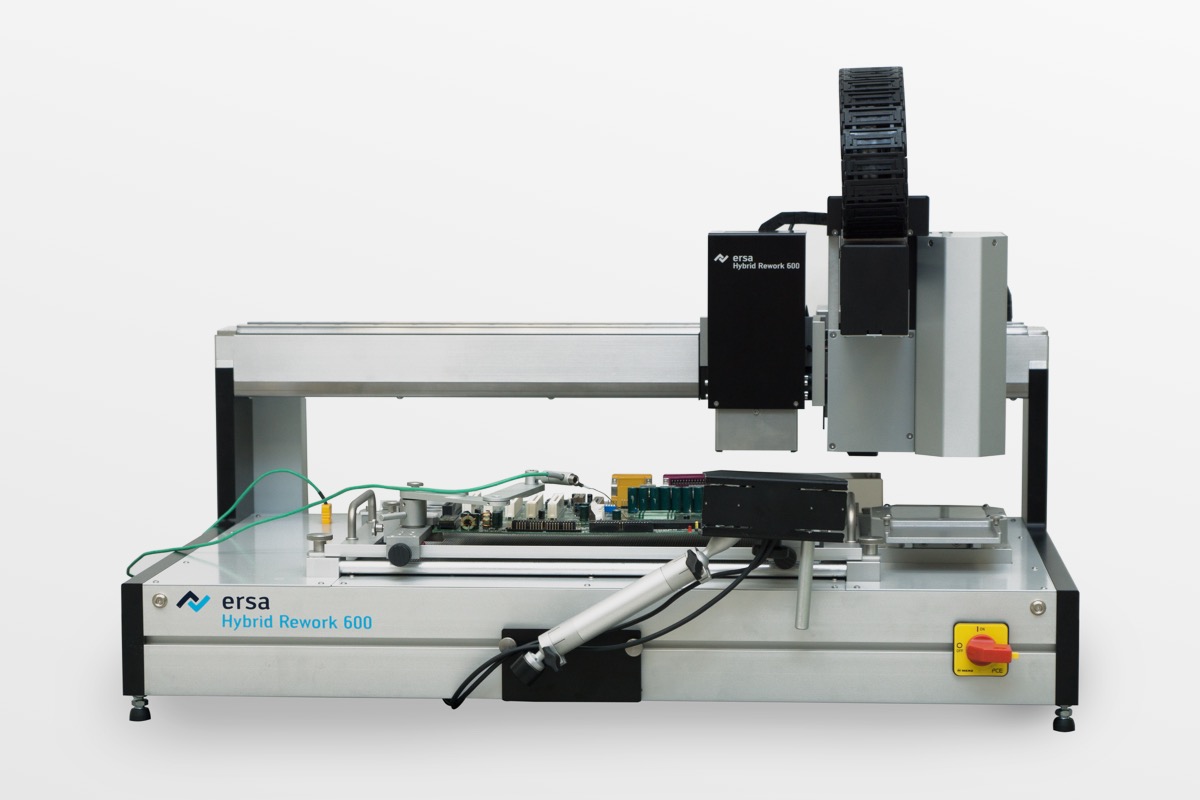

ERSA Hybrid Rework 600

Automated and precise repairs: Seamlessly desolders, places, and solders SMT components with machine vision accuracy, ensuring flawless rework for chips, connectors, and boards up to 535mm.

Efficient and reliable: The hybrid heating system delivers even heat distribution, preventing component damage and making it ideal for rework, prototyping, and low-volume production.

Cleaning

AQUBE LH-521 Aqueous

PCB Cleaning System

Eco-friendly and efficient: Utilises biodegradable cleaning agents for environmentally responsible and highly effective PCB cleaning.

Large capacity: Handles large batches, ensuring boards are free from contaminants, flux residues, and particles that could affect performance and reliability.

FAQ’s

Our PCB/CCA assembly services are distinguished by the latest technology including component verification systems (CVS) and precise assembly lines capable of handling a vast range of component sizes efficiently. We use advanced technology like vapor phase ovens and PTB aqueous washing machines, ensuring high-quality bonding and protection against environmental factors. Our commitment to precision, speed, and quality in every printed circuit board assembly sets us apart in the electronics manufacturing industry.

We are equipped to handle large-scale orders with our high-speed assembly lines and rigorous quality assurance processes. Our capacity for mass production, coupled with consistent quality control, ensures we can meet large order demands while maintaining the high standards of PCB assembly.

Yes, we are equipped to handle testing for high-volume electronic products. Our testing methodologies, including AOI and Functional Testing, are designed to keep up with the demands of high-speed manufacturing.